LVT Dry back vinyl floor (Glue down)

LVT Dry back 1.5mm,2mm and 3mm are pop selling and more acceptable in some south American countries, South East Asia countries, European and Australia countries also, Our Superior Floor provide 100% virgin only for these items, dry back /glue down this is more suitable for DIY better , even for a lady can be easy operating by hand , as production WITHOUT VOC EMISSION, natural wood design and Fire resistance well.

Superior floor™ have thousands of colors for your options, also can be customized according to specify colors , package can be print on your own logo. If you wana know more details , do not hesitate to contact us freely.

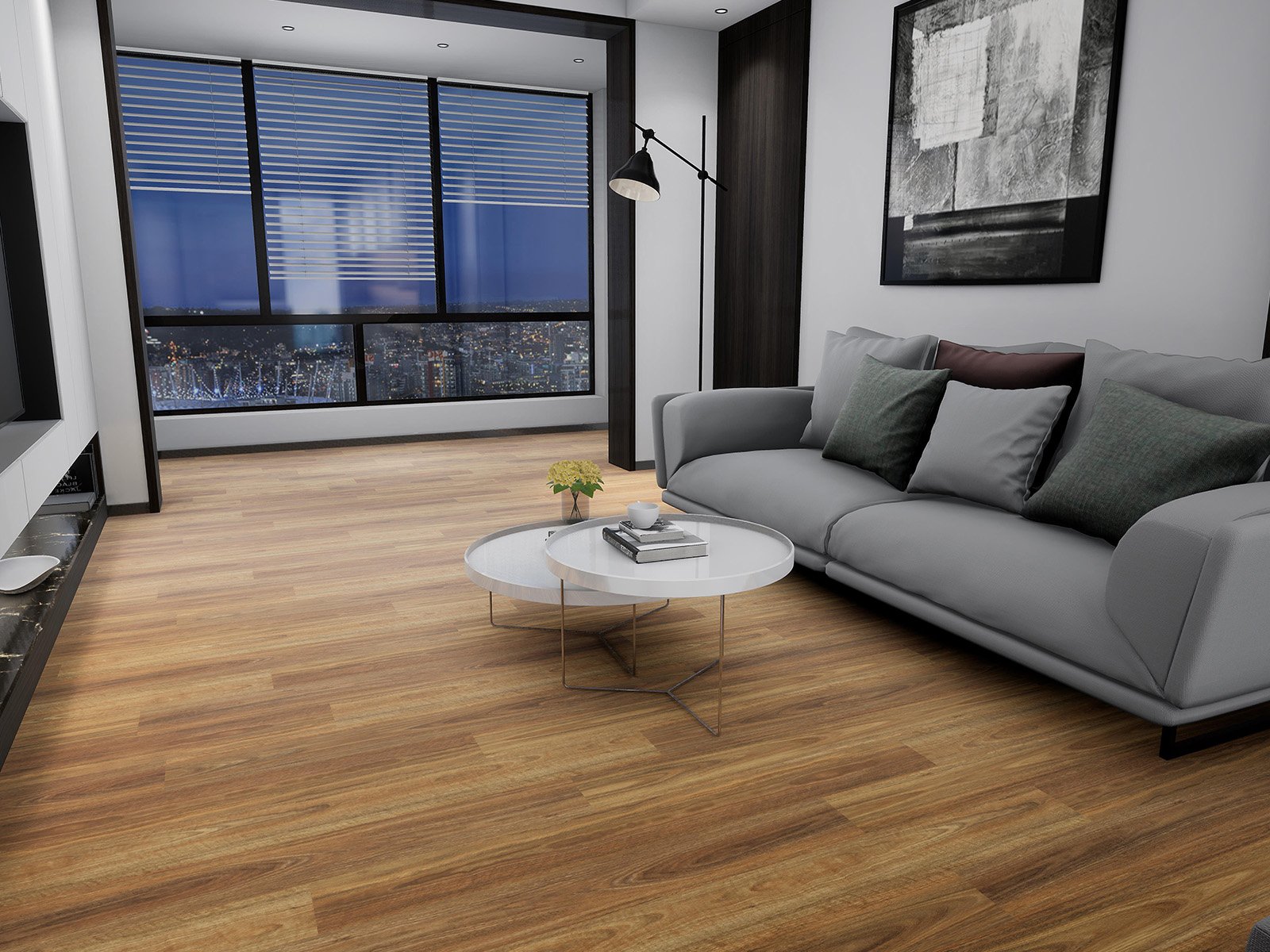

Here are some photos for your check from our project which we are working now:

| Product: | LVT Vinyl Floor |

| Color: | Wood Design/Stone Design |

| Package: | Palletized |

| MOQ: | 1*20ft Container |

| Payment Terms: | 30% T/T deposit. 70% T/T against copy of B/L or LC at sight |

| Lead Time: | 30~45 days |

| SPC Click | |

| Size: | 12*24”,6*36”,7*48”,9*60”,9*72” |

| Thickness: | 3.5mm,4mm,5mm,6mm |

| Wearlayer: | 0.3mm,0.4mm,0.5mm,0.55mm |

| Available for length 1.5m/1.8m | |

| Specially for Residential Use | |

| Available size: | |

| 12*24” | Thickness: 3.5mm,4mm,5mm,6mm |

| 6*36” | Wearlayer: 0.3mm,0.4mm,0.5mm |

| 7*48” | |

| 9*60” | |

| 9*72” | |

This is one of high resolution pictures which we designed for our client with perfect view. also have more colors can be recommend according to different requests. Anyway, it is right place you are checking on http://www.superiorfloor.cn

RECOMMENDED INSTALLATION GUIDE

TOOLS NEED:

ROOM CONDITIONS FOR INSTALLING OUR SUPERIOR FLOOR ™ PLANKS:

The optimum room temperature range shall be 65°F-70°F (18 °C- 21 °C ) for 24 hrs. before, during and after installation, and a humidity range of 40-60% is recommended. Do not remove the planks from the case during this acclimation period! Maintain this temperature during installation as well.

CHECK THE PLANKS BEFORE INSTALLING TO BE SURE OF APPEARANCE:

We maintain strict quality control at the factory, but it is a good idea to check each plank for blemishes or flaws.

SHUFFLE PLANKS FOR BEST VISUAL REPRESENTATION:

Our flooring replicates the look of a natural product with variation in color,texture and sheen/gloss. For best visual effect, shuffle planks from several cartons and do not install similar planks next to one another.